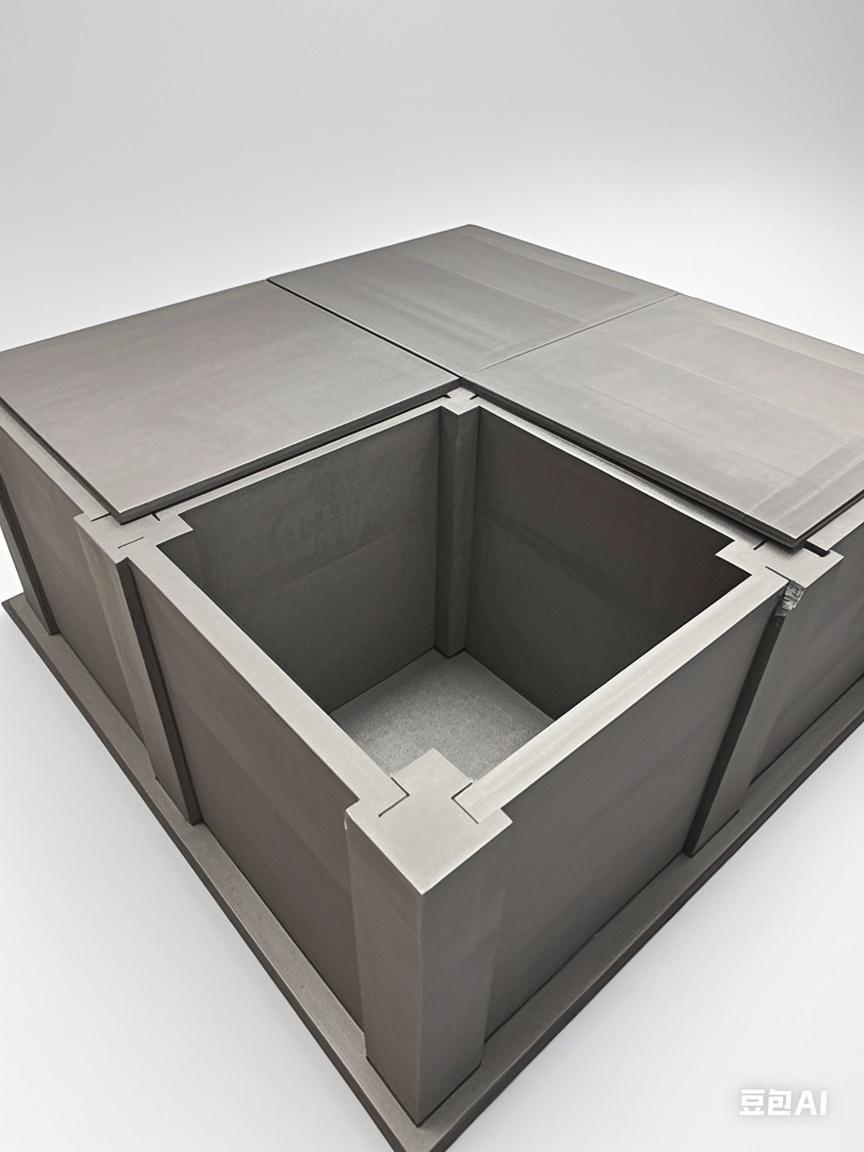

Graphite crucible is a type of equipment used for high-temperature melting, heating, and crystallization. The main raw materials of graphite crucibles are graphite, silicon carbide, silica, refractory clay, asphalt and tar.

Class:

1. Artificial graphite crucible

Artificial graphite crucibles are processed by graphite electrodes or high-purity graphite machines, and are widely used in the smelting of alloy tool steel and the smelting of non-ferrous metals and their alloys in metallurgy, casting, machinery, chemical and other industrial sectors, and have good technical and economic effects.

3. Graphite-clay crucible

Graphite-clay crucibles are mainly composed of natural flake graphite and clay. It is now only used when cast iron, cast steel is melted at high temperatures, and small amounts of precious metals are melted.

4. Graphite-silicon carbide crucible

Graphite-silicon carbide crucibles are mainly composed of natural flake graphite and silicon carbide. Most of the melting of non-ferrous metals such as copper and aluminum alloys uses crucibles made of this material. Now the demand for graphite-silicon carbide crucibles has accounted for about 97% of the total.

Characteristics:

1. It has good thermal conductivity and high temperature resistance

2. The thermal expansion coefficient is small, and it has certain strain resistance to rapid heating and cooling.

3. It has strong corrosion resistance to acid and alkaline solutions and has excellent chemical stability.