Graphite electrodes are mainly made from petroleum coke and needle coke as raw materials, with coal tar pitch as a binder. They are produced through processes such as calcination, batching, kneading, molding, baking, graphitization, and machining. They are conductors that release electric energy in the form of an arc to heat and melt the charge in an electric arc furnace. Depending on their quality indicators, they can be classified into RP, HP, and UHP graphite electrodes.

- Application:

- 1,For Electric Arc Steelmaking Furnace Electric arc steelmaking is a major user of graphite electrodes. In an electric arc furnace, graphite electrodes are used to introduce current into the furnace, generating a high-temperature heat source through an electric arc formed between the electrode tips and the charge materials for smelting.

- 2,For Submerged Arc Furnace Submerged arc furnaces are mainly used for the production of industrial silicon and yellow phosphorus, characterized by the lower part of the conductive electrode being buried in the charge material, forming an arc within the charge layer, and utilizing the thermal energy emitted due to the resistance of the charge material to heat it.

- 3,For Resistance Furnace Resistance furnaces include graphitization furnaces for producing graphite products, melting kilns for glass, and electric furnaces for producing silicon carbide. The materials loaded in the furnace act both as heating resistors and as the objects being heated.

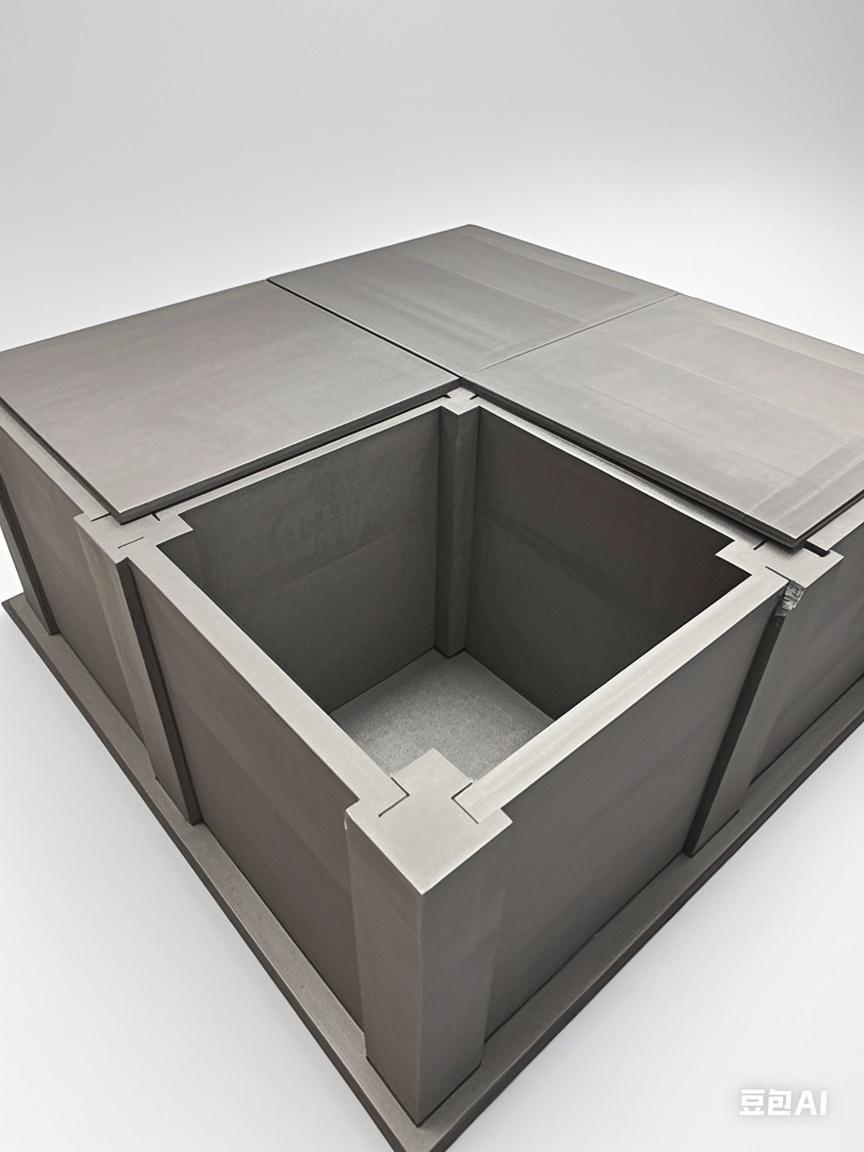

- 4,For Preparing Non-standard Graphite Products Graphite electrode blanks are also used to process various non-standard graphite products such as crucibles, molds, boats, and heating bodies.

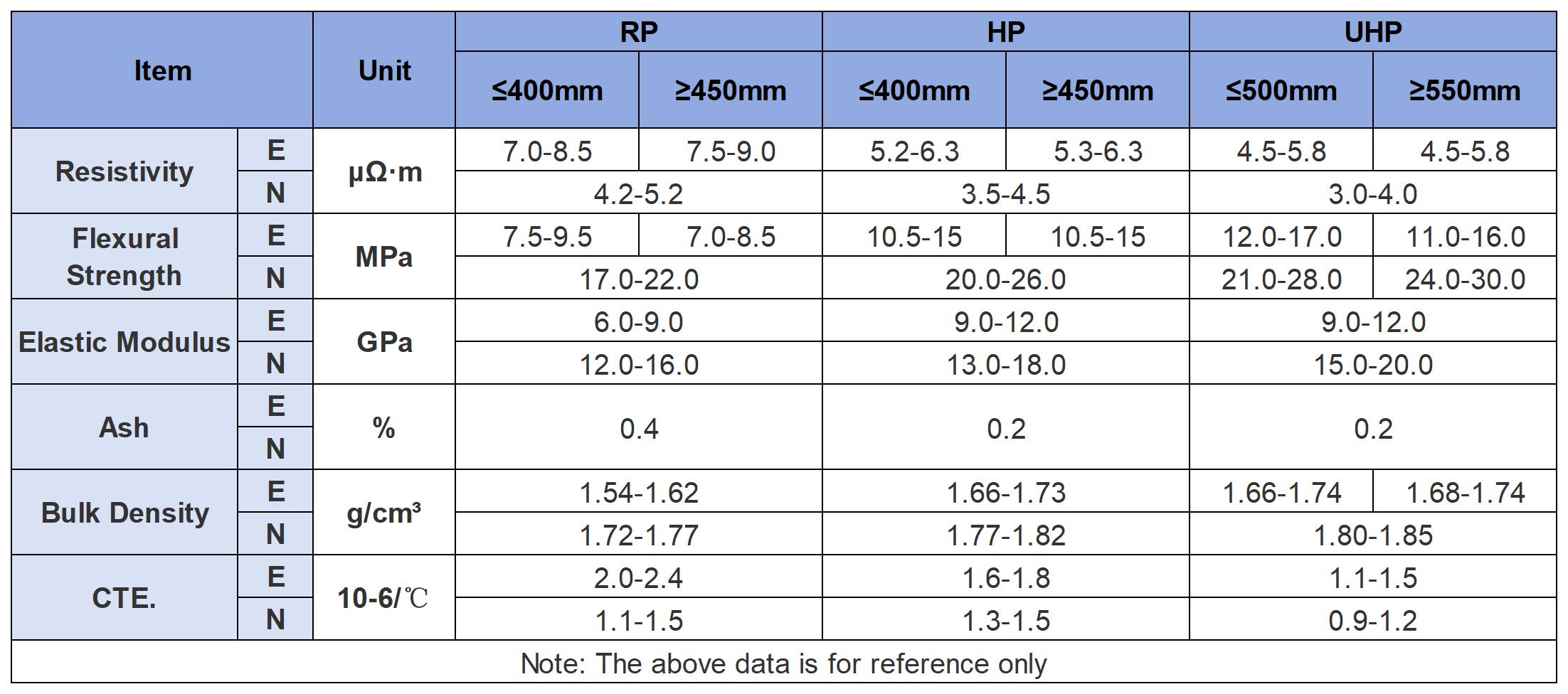

Specification: